The new Pro-Leveling tile leveling system

The Pro-Leveling tile leveling system is manufactured by our company in Poland.

It is made of the highest quality plastics, thanks to which it obtains the necessary strength parameters. Out of concern for the environment and natural resources, we partly use recycled materials in our production. Also our unit and bulk packaging are recyclable, and thus – reprocessable.

The Pro-Leveling system is a great tool for professionals as well as for first-time tile layers.

Our system has gained recognition on the European market and gained the trust of professionals.

We have made a lot of effort to ensure that our product is refined in every detail. Both the construction, material and durability have been designed and tested by specialists.

The Pro-Leveling tile leveling system consists of three elements:

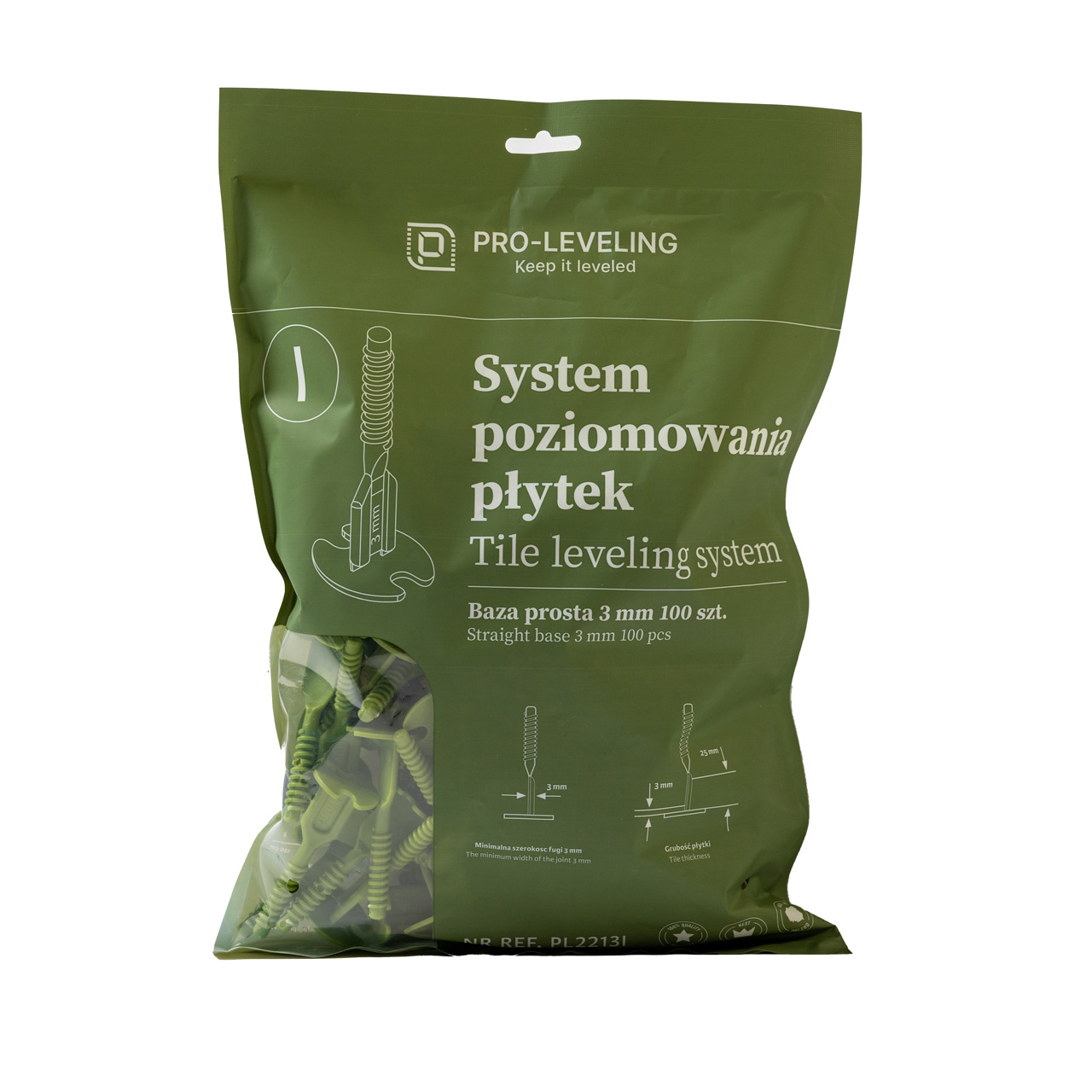

- Straight Base,

- Pad (optional),

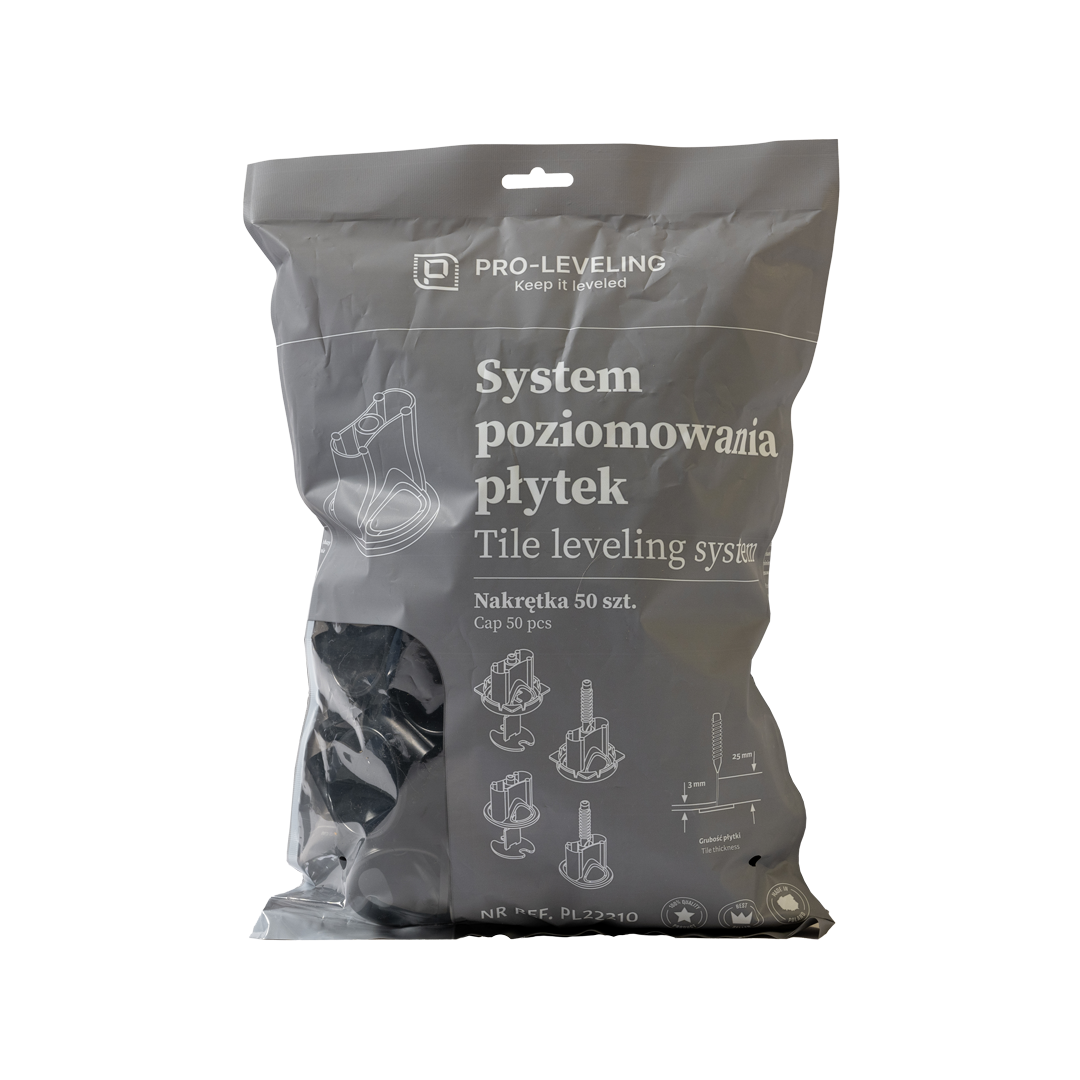

- Cap.

Straight base

The base is the basis of the Pro-Leveling tile leveling system and is available in three thicknesses defining the joint thickness – 1 mm, 2 mm and 3 mm.

A wider joint can be obtained by using standard tile crosses with a threaded base. The maximum possible joint is 8 mm. The minimum joint width is 1 mm.

Driver‑Drill adapter

The new dual-function adapter significantly speeds up the work for each user.

Using the adapter mounted on the Driver‑Drill, you can screw the caps on the bases very quickly. This way, you will save time, which is so important during each project. The adapter is also used to unscrew the caps from the used bases, thanks to which the caps are ready for use again in a few moments.

Levels unevenness

The system, thanks to its unique design, allows for perfectly even arrangement of tiles without the need to use a spirit level!

Speeds up work

Thanks to the Pro-Leveling system, you don't have to use additional tools, thanks to which you save time. Our specially patented thread makes the nuts screw onto the bases very quickly.

Easy to use

Our tile leveling system is intuitive and very easy to use even for people without experience.

No additional tools required

You don't need any additional tools such as a spirit level or pliers to tile with the Pro-Leveling system!

Reusable

Thanks to the use of high-quality material, our pads and caps can be used many times, which translates into significantly lower costs of your project!

Made in Poland

Our tile leveling system has been designed and manufactured in Poland from scratch.

Eco-friendly

The unique design process of the components and the production of partly recycled plastic allow you to save and reduce the weight of products, the size of the package, and thus the carbon footprint associated with production and logistics.

The highest quality

The Pro-Leveling system is made of the highest quality plastic mix, which makes it durable, and the caps and pads can be used many times.

The Pro-Leveling tile leveling system was created in such a way that, while maintaining its properties and the highest quality, it is easy to use for both professionals and people who have no experience in laying tiles.

Using the system consists of three simple steps and does not require specialized tools.

Step 1

After spreading the glue, fix the first tile, slide the threaded base under the edge of the tile (recommended minimum of 2 bases per edge), then attach the next tile, moving it to the edge of the previous tile.

Step 2

Attach the pad to the cap (optional) and screw the cap to the base, aligning the edge level between the tiles.

Step 3

After the glue has set, break the cap together with a part of the base with a vigorous blow along the joint (without unscrewing the cap), e.g. with a rubber hammer or a kick.

Remember, a kicked cap and pad can be reused!

Zastosowanie adaptera na wkrętarkę do systemu poziomowania płytek PRO-LEVELING

Step 1

Place the threaded base between the tiles and then put a cap on the base (optionally with a pad). After attaching the adapter to the screwdriver, you can start tightening. Remember not to set too much tightening force.

Step 2

Tighten the cap using the adapter until resistance is felt. To increase the precision of tightening, you can make the last turn with your hand. The plane of the tiles should be even.

Step 3

After the tile adhesive has bonded, break the cap together with a part of the base with a vigorous blow along the joint (without unscrewing the cap), e.g. with a rubber mallet hammer or a kick.

Step 4

Used remains of the threaded bases that are still in the caps, can be removed by grabbing the end of the base and unscrewing the cap with the other hand using the adapter.

| 15 cm | 89 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 20 cm | 67 | 50 | ||||||||

| 25 cm | 53 | 40 | 32 | |||||||

| 30 cm | 44 | 40 | 33 | 33 | ||||||

| 40 cm | 67 | 50 | 40 | 33 | 25 | |||||

| 50 cm | 53 | 40 | 32 | 27 | 20 | 16 | ||||

| 60 cm | 50 | 37 | 30 | 22 | 17 | 15 | 11 | |||

| 80 cm | 46 | 34 | 28 | 23 | 16 | 14 | 10 | 9 | ||

| 90 cm | 41 | 31 | 24 | 19 | 15 | 12 | 10 | 8 | 7 | |

| 120 cm | 36 | 27 | 22 | 18 | 14 | 10 | 8 | 7 | 7 | 6 |

| 15 cm | 20 cm | 25 cm | 30 cm | 40 cm | 50 cm | 60 cm | 80 cm | 90 cm | 120 cm |

The pad and cap can be reused many times. The foot of the base after breaking remains under the tiles and cannot be reused.

Due to the high-quality material used for production, the caps and pads can be used many times.

There is no system thanks to which the tiles will arrange themselves, the use of the latest technologies and tools will not replace physical work. However, it is important to use tools that will make customers happy with the quality of the tile laying. The lack of „steps” – the difference in levels between the tiles, is one of the most important parameters that distinguishes a true professional from a poor tile installer. It is also important for us to work quickly and without surprises.

Currently, with the market trend favoring large-sized tiles, laying them is almost impossible without the help of a tile leveling system. Therefore, if we want to achieve perfect results, we will not do it without this „tool”.

We always start tiling works with the analysis of the substrate on which we will lay our tiles. The substrate for the tiles should be clean, even and leveled. If it is too absorbent, an appropriate primer should be applied before tiling.

It is also important to maintain a regular grout – we often see uneven grout between the tiles. To avoid this, first of all, we must plan the arrangement of the tiles well, often it will be necessary to lay some of the tiles „dry” and determine the „starting” place. Then, attach the starting strip (regardless of whether it is a floor or a wall), from which we will start our work. This strip should be firmly attached to the ground and should be perfectly straight. The starting strip is one of the most important factors in the success of tiling works, affecting the perfect appearance of the laid tiles. As strips, you can use one or, if necessary, several ceiling profiles for gypsum boards, and even ordinary wooden strips – the condition is that they should be straight and attached „under a string” or with a laser device.

Do not forget about double gluing – spread the glue on the substrate with a notched trowel or other suitable tool, and on the underside of the tile spread a thin layer of glue with a smooth float.

Do not use low-quality glue. Well-glued tiles should please us for many years.

Next, we need to choose the appropriate tile leveling system, without which we cannot imagine tiling works nowadays. There are many systems, but our choice is the Pro-Leveling system.

Using the Pro-Leveling tile leveling system, we can be sure:

Significant acceleration of work

- First-class robot quality

- Perfectly even joints

- No differences in the height of the tiles

- Leveling surface unevenness

Avoid excess glue in the area of the threaded base, before laying the next tile, collect several millimeters of glue along the edge of the already laid tile. Thanks to this, we will avoid breaking the base above the tile, which will save us from scratching the remains of the plastic. Remember that the adhesive mortar after complete setting is as hard as concrete.

Remove the cap with the base part as soon as possible, usually the next day (depending on the adhesive manufacturer’s instructions). Removal involves a vigorous blow with a rubber hammer or shoe, without unscrewing the caps! The threaded base has a narrowing in its lower part at the foot, thanks to which it breaks off at the level of the lower edge of the plate. Then all we have to do is grouting.

Our first activity was a construction company which we ran for over 20 years, gaining extensive experience in the industry. Behind us are also many years of cooperation with many construction companies, with particular emphasis on tilers. When carrying out tiling work and testing many tile leveling systems, we noticed a lot of flaws in the existing systems. So we decided to develop our own system without any shortcomings.

After many months and many trials, in cooperation with competent engineers and the best toolmakers, we managed to create such a system, which we patented under the Pro-Leveling brand.

The Pro-Leveling tile leveling system is one of the best systems that facilitates and speeds up tiling work, thanks to which the result of our work is perfect. At the same time, it is probably the only wound up tile leveling system that does not break the thread in the cap during winding.

This is an extremely important feature. Perfectly glued tiles are one thing, but the comfort of work is fundamental for a tiler. At the same time, the Pro-Leveling tile leveling system can be used for tiles with a thickness of 3 to 25mm, which is also unique on the market.

Thanks to the work with the Pro-Leveling tile leveling system, the effects of work will be priceless.

World Distributors

France JS Distribution S.A.S. j.dardenne@jsdistribution.fr

Bułgaria LDL Remonti Ltd info@e-maistor.com

Czech Republic Huka stores s.r.o. info@huka.cz

United Kingdom DREAM BATHS LTD info@dreambaths.co.uk

Lithuania Aumata, UAB tomas@aumata.lt

Poland JN Invest Sp. z o.o. contact@pro-leveling.com

Germany

Spain

Contact us

We invite construction companies, wholesalers and shops to cooperate with us.

Due to the organization of our company, we do not accept retail orders.

Address

Wolbromska 18/1B

53-148 Wrocław